| 类型 | 水泥机械 |

|---|---|

| 品牌 | 鹏飞 |

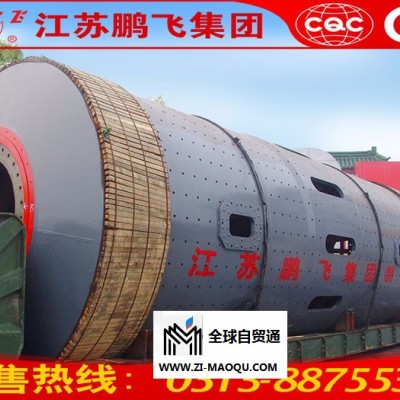

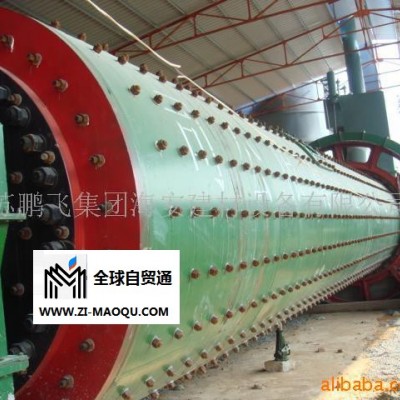

| 型号 | 1500 |

| 加工定制 | 否 |

鹏飞1500t/d回转窑水泥生产线工程

1.生产规模、生产方法与水泥品种Productionscale, production method and cement types

1.1生产方法 Production method

干法生产,设置一条φ3.5×54m带窑外分解炉五级旋风预热器回转窑生产线。

The productionmethod is dry process. A rotary kiln(φ3.5×54m) production line with five-stagecyclone pre-heater and decomposition furnace will be adopted.

1.2生产能力及工厂规模Production scale and capacity

烧成系统生产能力为日产熟料1500吨,掺加石膏后工厂年产硅酸盐水泥500000吨。

The productioncapacity is 1500t/d for clinker, while 500,000t/a for Portland cement whenmixed with gypsum.

1.3 水泥品种 Cement types

本技术和设备可生产符合中国水泥标准GB175-1999中的硅酸盐水泥,其强度为32.5MP、42.5MP,可根据市场需要进行调节。

The technologyand equipment adopted can produce 32.5MP and 42.5MP types of cement inaccordance with Chinese Standard GB175-1999. They can be adjusted according tomarket demand.

2. 原料燃料与配料

3. 工艺设计特点Main technical characteristics

3.1 为保证系统运转率,提高产品产、质量,设计中大量选用了具有二十世纪九十年代先进水平的新设备、新工艺,以提高生产线的装备水平,确保设计指标的实现。如新型五级旋风预热预分解系统、高效空气梁篦冷机,节能型多通道喷煤管,戴维森高温风机,鲁奇最新技术生产的电收尘(BS930)等,输送设备采用了耐用、节电的板链提升机、链式输送机,将使本工程的装备在同规模生产线中处于领先水平。

This productionline adopts advanced technology and equipment in 1990s to raise technical leveland to ensure design indexes. New five-stage cyclone pre-heater system, highefficiency air girder grate cooler, multi-passage pulverized coal burner,Davison heat temperature fan, Luqi BS930 electrical dust collector, as well aschain-board elevator, chain conveyor adopted in this production line can ensurethat the technology is advanced compared to other production lines with thesame scale.

3.2 在保证生产线的完整性、生产的连续性和可靠性的前提下,力求简化生产工艺流程,以便于生产管理,减少生产事故点,降低投资。

If it has notbad influences on completeness,continuity and reliability, processprocedures will be simplified to enhance production management, reduce troublesand lower investment.

3.3 工艺布置上,简化设备厂房,减少建筑面积 Simplifying houses for equipment todecrease building area

库顶露天布置;高温风机露天布置;带式输送机通廊不设屋顶,用玻璃钢防雨罩防雨;取消提升机楼;收尘器露天放置。

Top of silos arewithout covers, heat temperature fan and dust collectors are open arranged andglass fiber rainproof covers instead of roofs will be set for belt conveyorpassages. There will be no building for bucket elevator.

对各种原料、半成品和成品,在满足正常生产要求的前提下,合理减少储存期,并尽量采用堆棚储存。土建费用大幅度降低。

If it has notbad influences on normal production, by properly reducing storage periods forall raw materials, semi-product and finished product and adopting shed to storethose materials and products, civil engineering costs will be greatly reduced.

改进窑尾工艺布置,窑尾预热器塔架设计为钢结构,既可加快施工安装进度,节省投资,又可美化建筑。

frame forpre-heater at kiln inlet will adopt steel structure to save investment,accelerate erection speed and beautify building.

3.4 充分考虑节能、降耗,生料入窑使用节能型的板链式提升机和空气输送斜槽,提高了系统的运行可靠性,降低了输送能耗。

Measures havebeen taken to save energy and reduce consumption. using chain-board elevatorand air slides, reliability of the system is enhanced and conveying energyconsumption is decreased.

3.5 加强计量。除生料配料采用电子皮带秤计量外,各进厂原料、入窑生料、入窑煤粉、出窑熟料、出库熟料都设置了相应的专用计量设备,为工厂的科学管理提供了依据。

All necessaryparts will adopt measuring equipment to guarantee scientific management. Forexample, there are measuring equipment at those parts such as raw mealblending, raw materials entering into plant, raw meal feeding to kiln, pulverizedcoal feeding to kiln, clinker outgoing kiln and clinker outgoing silos.

3.6 保护环境,采取有效措施严格控制排放废气的含尘浓度在规定范围内。在生产工序中的各扬尘点,针对不同的废气特性,设置与之相应的新型高效专用收尘设备。

Effectivemeasures have been taken to guarantee strict environment protection standards.Different efficient dust collectors are set at all dust producing pointsaccording to different characteristics of waste gas.

4.技术方案Technical plan

4.1 生产工艺Production process

4.1.1 生产规模、生产方法与产品方案Production scale, production method andproduct plan

本项目采用新型干法生产工艺,建设一条日产1500吨熟料的新型干法水泥生产线。煅烧设备采用φ3.5×54m回转窑,窑尾采用带五级旋风预热器和分解炉的预热分解系统。

A new dryprocess production line with capacity of 1500t clinker per day will be built. Arotary kiln(φ3.5×54m) will be used as burning equipment. Five-stagecyclone pre-heater and decomposition furnace will be adopted at kiln inlet.

4.1.2 主机设备选型和主要生产设施配置Selection of main equipment andproduction facilities

4.1.2.1 石灰石破碎Limestone crushing

石灰石破碎选用单段锤式破碎机,本破碎机适用于破碎中等强度的脆性矿石,如石灰石、泥灰岩、页岩、石膏和煤等,入料粒度大,可一次将大块原矿破碎到符合入磨粒度。此外,由于本机采用顺向排料篦子,对矿石中的水分和泥土有更强的适应性。本机具有特殊的进铁保护,对混入机内不能破碎的金属异物,将反弹到给料机上,操作人员可根据异样金属声停机处理。

Single-stagehammer crusher is used for limestone crushing. This type of crusher is suitablein crushing medium strength ore such as limestone, marlite, slag, gypsum andcoal. It can crush big ore to required size. Moreover, it can crush ore whichhas moisture and earth in it because it adopts discharging grates in the samedirection. It has special iron feeding protection device, which can rebound theuncrushed metals to the feeder, so the operator can stop it if he hearspeculiar sound to deal with this matter.

本项目石灰石破碎采用TKPC16.18单段锤式破碎机,给料粒度800mm,生产能力250t/h,年利用率25.51%。

Limestonecrushing will adopt TKPC16.18 single-stage hammer crusher adopted. Feeding sizeis 800mm, production capacity is 380t/h and annual usage rate is25.51%.

4.1.2.2 生料粉磨Raw meal grinding

对1500t/d生产线而言,生料粉磨可供选择的有HRM2800m立磨粉磨系统。

For 1500t/dcement production line, available raw mill system is HRM2800m mill system.

4.1.2.3 生料均化与储存Raw meal homogenizing and storage

本设计采用一座集生料储存、均化于一体的φ15×50mMF均化库,生料储量6500t,储存期2.86d。

φ15×50mMF siloboth can homogenize and store raw meal will be adopted. Its capacity is 6500tand storage period is 2.86days.

4.1.2.3 烧成系统 Clinkering system

熟料烧成采用一套单列五级CDC预分解系统、φ3.5×54m回转窑和第三代新型空气梁篦式冷却机等设备组成的窑外分解煅烧系统。日产熟料1500t/d,熟料烧成热耗840Kcal/kg (3511.0KJ/kg),入窑生料的CaCO3 分解率大于90%。系统废气余热用于烘干原料和原煤。

A five-stagecyclone pre-heater system with CDC, φ3.5×54m rotary kiln and new air girdergrate cooler, etc will be adopted for clinker preparation. The capacity is1700t clinker per day. Clinkering heat consumption is 840Kcal/kg (3511.0KJ/kg). Decomposition degree of CaCO3 islarger than 90%. Extra heat of waste gas is used for drying raw materials andraw coal.

熟料冷却采用引进技术、中国制造的新型第三代空气梁篦冷机,篦床有效面积为61.8m2,产量62.5t/h,出冷却机的熟料温度为环境温度+65℃。

The new type airgirder grate cooler manufactured in China with imported technology will beadopted for clinker cooling. Effective area of grate bed is 61.8m2. Output is62.50t/h. Outgoing temperature of clinker is 65℃ higher thanambient temperature.

4.1.2.4水泥粉磨Cement grinding

本项目水泥粉磨选用两台φ3.5×13m管磨,配置N-1500型O-SEPA高效空气选粉机组成圈流粉磨系统,台时产量50t/h。

Twoφ3.5×13mmodel tube cement mills equipped with N-1500 model O-SEPA air separator will beadopted for cement grinding. Its capacity is 50t/h per set

4.1.3工艺主机设备表List of main equipment

4.1.4 生产工艺过程Process procedures

4.1.4.1 石灰石破碎及预均化Limestone crushing and pre-homogenizing

石灰石破碎站设在厂区,采用单段破碎系统,其工艺流程为:矿区开采的石灰石由汽车运输进厂,卸入破碎站内石灰石料仓,经料仓下可调速的重型板式给料机喂入TKPC16.18锤式破碎机进行破碎,破碎机额定产量为250吨/时,破碎后的矿石(粒度≤25mm)由出料带式输送机输送入石灰石预均化堆场进行预均化和储存。预均化好后石灰石带式输送机送入配料库。

Limestonecrushing workshop is set inside the plant, which adopting single-stage crushingsystem. Limestone exploited in mining area will be transported into plant bytrucks and unloaded into hopper in the limestone crushing workshop, and thenfed onto TKPC16.18 hammer crusher by speed-governable heavy apron feeder. Ratedcapacity of crusher is 250t/h. Crushed limestone (size:≤25mm) will be fed ontothe limestone pre-homogenizing stockyard by belt conveyor. Then the limestonewill be fed onto material blending bin by belt conveyor.

为避免粉尘污染,破碎车间设有气箱脉冲袋收尘器一台,抽取破碎机及带式输送机下料处的含尘气体,经收尘器净化后的气体由排风机排入大气。

To avoid dustpollution, an impulse bag filter will be used to collect dust from crusher anddischarging points of belt conveyor. Purified air will be drained to theatmosphere.

4.1.4.2粘土、砂、石膏及铁粉、混合材输送 Crushing of slag, gypsum; Conveying ofiron powder and admixture

由汽车运入厂区的粘土、石膏等生产辅助原料,分别卸入破碎站料仓内,经料仓下可调速的板式喂料机喂入破碎机进行破碎,破碎后的物料由出料带式输送机转运至辅助原料堆场。

clay and gypsumwill be transported into plant by trucks and unloaded into different bins inthe crushing station, and then fed onto crusher by speed-governable apronfeeder. Crushed materials will be fed onto auxiliary materials stockyard bybelt conveyor.

铁粉、混合材经破碎系统输送皮带机送入辅助原料堆场。

Iron powder andadmixture will be fed onto auxiliary materials stockyard by belt conveyor.

4.1.4.3 原料配料Raw material blending

配料站内设一座φ8×14m圆仓储存石灰石;另设置三座配料仓,储存粘土、砂、铁粉,储量分别为360t和150t。参与配料的粘土、砂、铁粉和石灰石分别由库底调速链板机、电子皮带秤按设定的配比卸出,经带式输送机送至生料磨。

Four bins willbe set for material blending: one for limestone (φ8×14m), one forclay(capacity: 360t)、sand (capacity: 360t) and one for ironpowder (capacity: 150t). Speed-governable chain-board conveyors and electricbelt balances will be used at the bottom of material blending bins. Materialswith required proportion will be fed onto the raw mill by belt conveyor.

由多元素荧光分析仪和微机组成的生料质量控制系统,可自动分析出磨生料成分,并根据分析结果和设定的目标值自动调节电子皮带秤转速以控制各原料的下料量,确保出磨生料成分合格

Raw meal qualitycontrol system consists of fluorescent light analyzer and computer. It canautomatically analyze raw meal composition and automatically adjust rotaryspeed of chain-board conveyors and electric belt balance according to analysisresult and target value, so that discharging amount of each kind of materialcan be controlled.

4.1.4.4生料粉磨及废气处理Raw meal grinding and treatment of wastegas

来自库底皮带输送机的配合原料,经磨头锁风装置喂入HRM2800立磨粉磨,出磨成品由旋风分离器收集经链式输送机、斗式提升机送至生料均化库,磨尾废气至窑尾电收尘器净化处理,然后排入大气。磨机生产能力:当产品细度为0.08方孔筛筛余≤12%,入磨物料粒度≤40mm。水分入磨时≤6 %,出磨时小于0.5%,台时产量为130吨,入磨气体温度控制≤350℃,热源利用废气。生料磨的年运转率为60.9%。烘干热源来自窑尾高温风机排出的部分废气。

Proportioned rawmaterial will be fed onto the raw mill by belt conveyor. The mill ismiddle-discharging drying mill which can dry material and grind material. Itscapacity is 150t/h. Drying heat is from waste hot gas drained by hightemperature fan at kiln inlet. Gas temperature is 300℃. Drying heat is from waste hot gas drained by hightemperature fan at kiln inlet.

4.1.4.5窑、磨废气处理Treatment of waste gas of kiln and mill

窑尾预热器的废气,经高温风机排出,一部分送至原料粉磨作烘干热源,其余部分经增湿塔调质后,与原料磨排出的废气汇合,进入袋收尘器净化,由排风机排入大气。当原料磨停运时,窑尾预热器排出的废气则全部进入增湿塔。废气处理系统收下的粉尘经链运机、提升机等输送设备送入生料均化库或生料称重仓;当增湿塔工作不正常,收下的窑灰水分过大时,增湿塔下面的螺旋输送机反转可将湿窑灰排出,再由人工用小车推走。

Waste gas fromthe pre-heater will be drained by high temperature fan. Some of it will be sentto raw material grinding section as drying heat. The other part will beadjusted by humidification tower, then mix with waste gas drained from raw milland purified by bag filter, after that, it will be drained to the atmosphere byfan. When the raw mill is stops, all the waste gas from the pre-heater will besent to humidity tower. Dust collected by waste gas treatment system will befed to raw meal homogenizing silo or raw meal weighing bin by chain conveyorand elevator. When working of humidity tower is not normal and collected kilndust has much moisture, screw conveyor under humidity tower will reverse anddrain out wet kiln dust. Manual car will move away the dust.

在系统布置上,窑、磨废气处理系统与生料磨和预热器塔架呈环状矩形布置,排废气的钢烟囱依附在预热器塔架上,不但布置紧凑、占地少,而且废气管道短,节省投资。

Waste gastreatment system, raw mill and pre-heater frame are rectangular arranged. Steelchimney is attached to pre-heater frame. The arrangement is compact and earthsaving. Moreover, waste gas pipe is short, so investment can be saved.

4.1.4.6生料均化Raw meal homogenizing

设置一座储量为6500吨的φ15×50m多股流(MF)均化库储存、均化生料。从生料磨来的合格生料由提升机送至多股流(MF)生料均化库顶,经库顶生料分配器分流后呈放射状从库顶多点下料,使库内料层几乎呈水平状分层堆放,出料则由库底充气系统分区供给松动空气,竖向取料后进入库底混合室。卸料时,向两个相对的料区充气,生料受气力松动并在重力作用下在各卸料点上方形成小漏斗流,生料在自上而下的流动过程中进行重力混合的同时,各卸料孔漏入卸料槽的生料从不同的半径位置上向库中心室流动,在流动过程中进行着径向混合,各卸料槽流入中心室的生料在充气的作用下再获得一次流态化混合,进入库底混合室后,在混合室内进一步充气搅拌混合均化。出库合格生料经空气输送斜槽、斗式提升机送入设在库顶的生料喂料仓,出喂料仓的生料经计量后,用斜槽和斗式提升机直接喂入预热器系统。

A MF raw mealhomogenizing silo (size:φ15×50m, storage capacity: 6500t ) is set. Qualifiedraw meal from raw mill will be sent to top of raw meal homogenizing silo bybucket elevator and discharged by silo top distributor. At the bottom of silo,raw meal will be loosened by aeration system and then discharged to mixing binunder silo. Raw meal will be further loosened and homogenized in the mixingbin. Qualified raw meal will be fed to raw meal weighing bin at the top of siloby air slide and bucket elevator. Weighed raw meal will be fed to pre-heater byair slide and bucket elevator.

均化所用高压空气由库底罗茨风机提供。

High pressureair for homogenizing is supplied by Roots blower under homogenizing silo.

4.1.4.7窑尾预分解及熟料煅烧系统Kiln inlet pre-decomposition and clinkerburning system

熟料煅烧采用φ3.5×54m回转窑,窑尾设有单系列五级低压损型旋风预热器和CDC型分解炉,熟料烧成热耗850Kcal/kg.cl(3552.0KJ/kg),日产水泥熟料1500吨。

A rotary kiln(Ф3.5×54m), low-pressure-loss five-stage cyclone pre-heater and CDCdecomposition furnace are adopted for clinkering. Clinker capacity is 1500t/d,clinker heat consumption: 840Kcal/kg.cl(3511.0KJ/kg). Coal usage ratio of kiln anddecomposition furnace is 40:60. Apparent decomposition rate of raw meal feedingto kiln is about 90~95%.

来自均化库的合格生料计量后进入预热器,逐级预热后进入分解炉,分解后的生料再进入回转窑内煅烧。分解炉所用的三次风来自窑头罩。

Weighed raw mealwill be fed to pre-heater. After heating, it will be discomposed indecomposition furnace and then fed to kiln. Third air for decomposition furnaceis from kiln hood.

为防止预热器系统结皮堵塞,除在旋风筒下设有膨胀仓外,还配有独特的自动控制喷吹系统以及必要的空气炮,保证预热器系统的正常运行。

To avoid jam,expansion bin and automatic-control blowing system and necessary compressed airdevices will be adopted to guarantee normal running of pre-heater.

从回转窑进入篦冷机的高温熟料,由篦板下鼓入的冷空气急速冷却,出篦冷机的熟料温度为环境温度+65℃,冷却、破碎后的熟料由链斗输送机送入熟料库。

Hot clinkerfeeding to great cooler will be cooled rapidly by cold air from blower undergrate board. Outgoing clinker from grate cooler is 65℃ higher than ambient temperature. Then clinker will befed to clinker silo by bucket-chain conveyor.

出篦冷机高温废气一部分作为窑用二次空气入窑;一部分由三次风管送到分解炉作为燃烧空气;剩余废气经窑头电收尘器净化处理后排入大气。电收尘器收下的粉尘经链运机送到熟料链斗机上入熟料库。

Hot waste gasfrom grate cooler is divided into four parts: part of it is sent to kiln assecondary air, part of it is sent to decomposition furnace as burning air bytertiary duct, and the rest is drained to the atmosphere after purified byelectric dust collector at kiln head. Dust collected by electric dust collectorwill fed to bucket-chain conveyor by chain conveyor.

4.1.4.8熟料储存Clinker storage

出冷却机的熟料由链斗输送机送入两座φ18×36m熟料库中储存。总储量26000吨,储存期17天。为方便熟料外运,库侧设有熟料散装系统。

This sectionwill adopt two silos with the size of Φ18×36m. Total capacity is 26000t andstorage period is 17days. Lateral clinker bulking systems is set at the side ofsilos.

熟料由库底计量设备卸出后,用带式输送机送入水泥磨。

Clinker will befed to cement mill by belt conveyor after discharged by weighing machines atthe bottom of silos.

4.2.5.9水泥配料及粉磨Cement blending and grinding

粉磨系统设一座石膏配料仓。配料仓由仓底微机配料秤按设定的比例搭配,熟料由库底微机配料秤按设定的比例搭配后,由带式输送机送入水泥磨内粉磨。

A gypsum bin isadopted. Computerized balance under the gypsum bin will be used for materialblending. The clinker and gypsum will be fed to cement mill by belt conveyorafter proportioned according to cement modulus requirements.

水泥粉磨选用两套由φ3.5×13m管磨机和N-1500型O-SEPA选粉机组成的闭路粉磨系统,台时产量50t/h。出磨后的水泥用斗式提升机和空气输送斜槽送入O-SEPA选粉机中分选,粗粉返回磨内再次粉磨;成品随气流进入气箱脉冲袋收尘器,被收集下来后由空气输送斜槽和斗式提升机送入水泥库中储存。

Twoφ3.5×13mmodel tube cement mills equipped with N-1500 model O-SEPA air separator will beadopted for cement grinding. Its capacity is 50t/h per set. Cement dischargedfrom cement mill will be fed to O-SEPA air separator by bucket elevator and airslide. Coarse powder will return to mill for regrinding. Finished product willbe sent to impulse bag filter. After collected by the bag filter, it will befed to cement silo by air slide and bucket elevator.

4.1.4.10水泥储存Cement storage

设4座φ15×41m带减压锥的水泥均化库储存出磨水泥,总储量28000t,储期15天。均化用气由库底罗茨风机供给。

Four silos(size:φ15×41m; total storage capacity: 28,000t, storage period: 15days)equipped with depressurizing cones will be used for cement storage. Air usedfor homogenizing is supplied by Roots blowers under cement silos.

4.2.5.11水泥包装及成品库Cement packing and finished productstorehouse

水泥包装选用二台八嘴回转式包装机,每台包装能力为100t/h。

Two 8-spoutpackers will be used for cement packing. Packing capacity is 100t/h per set.

来自水泥库均化后的水泥由提升机送入振动筛,筛去杂物后进入衡压仓,再进入八嘴回转式包装机包装成袋装水泥,由带式输送机送至24×70m成品库内堆放。

Cement will befed to vibrating screen by bucket elevator. Then cement will be fed to constantpressure bin. After that, it will be packed by eight-spout packer and transportedto finished product storehouse by belt conveyor.

水泥包装时,每袋重量由电子秤计量和调节。

Weight of baggedcement is weighed and adjusted by electric balance.

包装系统设有完善的除尘设施,可保证废气达标排放。

Good dustcollecting system is set for cement packing to guarantee dust emission standard.

4.1.4.12 中央化验室 Central lab

厂区内设一座中央化验室,负责进出厂原料、燃料、半成品和成品的常规化学分析及物理检验,以保证全厂各生产环节的产品质量,对水泥产品质量进行调度、管理和监督。

A central lab isset in the plant to carry out normal chemical and physical tests of rawmaterials, fuel, semi-products and finished product, guarantee product qualityin each section and adjust, manage, monitor quality of cement product.

4.1.4.13 工艺生产流程图 Process flow sheet

本工程生产工艺流程见图。Refer to related drawing.

4.1.5 计量设施 Weighing facilities

为加强生产各个环节的管理,执行相关计量法规,掌握各个工段生产状况。本项目从原燃料进厂到水泥成品出厂的各个工段设置了计量设施,并在机构配置上设有专门计量管理人员,对计量设施进行管理、维护,使工厂达到计量合格要求。具体配置见表。