| 品牌 | 四信机械 |

|---|---|

| 型号 | BQGA型 |

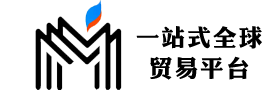

BQG系列油类粘液体半自动灌装机

BQG-2型油类粘液体半自动灌装机采用活塞

定量灌装原理,双速控制流量,先快后慢,防止液体外

溢,防漏灌装嘴,保证灌装过程中容器的清洁.该机设

计合理,操作简单,维护方便.缸桶及管到均采用不锈

钢制造,活塞采用尼龙材料制造.广泛应用于润滑油,

植物油,饮料,化工产品等粘液体的灌装.

主要技术参数:

灌装头数:2头

灌装范围:150-1000ML

灌装精度:+-1%

灌装速度:600-1000瓶/时

气源压力:0.4-0.8MPA

适应瓶高:150-300MM

四头半自动食用油灌装机采用先进的plc控制各执行汽缸来实现食用油的灌装。智能化自动进料,可自动控制油泵或高位罐自动进料。人工上下瓶,自动灌装,只需用脚踩动开关,即可实现设备的灌装工作。采用液体自重,通过改变灌装时间即可轻松完成灌装机计量的调整。数字化电器及气动控制,是灌装机的维修异常简单。该灌装设备采用**不锈钢制造,达到**卫生标准。

本机特点有:

1.灌装范围大。100ml-6000ml均可进行灌装,

2.灌装精度高。可达到0.5%的灌装精度,

3.自动进料,无需人工看管,

4.计量调整简单快速,仅需改变plc里的一个数值即可

达到灌装量的调整。

5.设备维修简单,易损件少,无需专业人员也可进行维

修工作。

6.操作简单,无需专业操作人员即可进行设备的使用。

主要技术参数:

序号 | 型 号 | ZHGA-2 | ZHZA-4 | ZHGA-6 | ZHGA-8 | ZHGA-10 | ZHGA-12 |

1 | 灌装头数 | 2 | 4 | 6 | 8 | 10 | 12 |

2 | 灌装容量 | 100-10000ml | |||||

3 | 生产能力(瓶/小时) | 350-500 | 600-1000 | 1000-1500 | 1500-2200 | 1600-2200(5L瓶计) | 1800-2600 (5L瓶计) |

4 | 灌装精度 | ≤0.5% | |||||

5 | 电 源 | 50HZ/60HZ 3N-380V 土 10% | |||||

6 | 功 耗 | 0.75KW-7.5KW | |||||

7 | 配用气源压力 | 0.5-0.8MPa | |||||

8 | 工作压力 | 0.6-0.7MPa | |||||

灌装机工作视频:www.88742966.com | |||||||

四川省邛崃市四信灌装机销售中心是一家专业销售、安装、维修食用油灌装机、酒水、饮料、油类及酱油、醋等液体灌装机的企业。四信灌装机销售中心技术专业、服务优良、客户遍布四川、湖北、贵州、广州、新疆、西藏各省。主导产品有高精度灌装机,烘干机,气动旋盖机,食用油灌装机及其他油类灌装机械,直列式微电脑灌装机等。产品质量可靠,操作简单,定量准确,工作效率高,符合**标准,适合各种瓶型,是大、中、小企业理想的生产设备。

“诚信、守信、信心、自信”是四信灌装机销售中心的经营宗旨。我们一贯秉承着“四信”的经营作风,为每一位客户提供方便快捷**的服务和**的灌装机及灌装设备产品。所有设备保修壹年,配件常年供应。

本部坚信“只有良好的信誉和服务,才能保证长久的销售”欢迎各界新老客户前来洽谈业务。

This machine is one kind by the microcomputer (PLC) programmable control, the photoelectricity sensing, the air operated execution fills in a body high technology and new technology installs the equipment. The this aircraft uses in food class specially, for example: White liquor, soy sauce, vinegar, seasoning, vegetable oil, syrup, mineral water and so on edibility the liquids as well as the agricultural chemicals chemical industry class liquid fills the attire. Fills installs the measurement to be precise, does not have the air bubble, does not have the dripping of a water clock. Suitably (including leads bottle) fills the attire in 50-1000ml each kind of bottle.

①The advanced design

this machine is suitable in the different specification vessel fills the attire, may cut in several minutes fills installs the specification.

Fills installs the cycle short, productivity is high.

The replacement fills installs the specification not to need to increase the spare parts, only must make the adjustment then to complete.

The user may act according to own productivity choice to fill installs quantity to determine fills the pattern number.

The touching type operation colored tablet, may demonstrate the production condition, the operation sequence, fill install the way and so on. The picture direct-viewing, the operation simple, the maintenance is convenient.

Each fills the pattern to be equipped with the card bottle mouth establishment, to guarantee the note material to be accurate to the position.

②Unique fills installs the way

design to select the straight line type to group the bottle, the bottle way, causes to fill installs the function to expand, each kind of shape vessel, all can fill the attire effectively in this equipment.

Selects the international advanced gas to fill installs the valve, guarantees fills installs the process not to have the dripping of a water clock, not to drool.

The formidable PLC software support, may realize ideally fills installs the work.

The man-machine friendly contact surface, all operations complete on the touching type colored tablet.

③The precise measurement control

fills the attire to use the fixed flow channel parameter, the control fills installs the time to realize the different measurement to fill the attire.

The pneumatic valve fills the precise time which installs to be possible to establish to 0.01 second, can cause the measurement precision control at±1% erroneous scope, reduces the nonessential material loss, enhances the user economic efficiency.

Each fills the pattern the measurement to be possible to carry on the independent control, realizes fills installs the measurement the consistency.

The this aircraft established has entered the bottle technology procedure, does not have the bottle, the counting does not arrive does not fill the attire, only then when the counter recorded the bottle number filled the bottling number consistently with the hypothesis when only then starts to fill the attire.

Fills the load how many, may carry on when initially moves must fill the load, again carries on the trimming, then obtains ideally fills installs the measuring accuracy.

④The technical reference

fills installs the scope 50~1000 milliliters

to fill installs the speed <90 bottle/The minute (refers to 100~500 milliliters scopes)

to measure the precision±1%

rated power 0.8 kilowatt

working voltage 220 volt

work barometric pressure 6~7 kilograms/Square centimeter

gas consumption 0.5 cubic meter/Minute

machine net weight 650 kilogram

external dimensions 2000×870×1900 millimeter