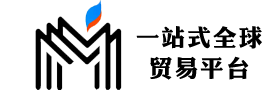

This machine is one kind by the microcomputer (PLC) programmable control, the photoelectricity sensing, the air operated execution fills in a body high technology and new technology installs the equipment. The this aircraft uses in food class specially, for example: White liquor, soy sauce, vinegar, seasoning, vegetable oil, syrup, mineral water and so on edibility the liquids as well as the agricultural chemicals chemical industry class liquid fills the attire. Fills installs the measurement to be precise, does not have the air bubble, does not have the dripping of a water clock. Suitably (including leads bottle) fills the attire in 50-1000ml each kind of bottle. ①The advanced design

this machine is suitable in the different specification vessel fills the attire, may cut in several minutes fills installs the specification.

Fills installs the cycle short, productivity is high.

The replacement fills installs the specification not to need to increase the spare parts, only must make the adjustment then to complete.

The user may act according to own productivity choice to fill installs quantity to determine fills the pattern number.

The touching type operation colored tablet, may demonstrate the production condition, the operation sequence, fill install the way and so on. The picture direct-viewing, the operation simple, the maintenance is convenient.

Each fills the pattern to be equipped with the card bottle mouth establishment, to guarantee the note material to be accurate to the position.

②Unique fills installs the way

design to select the straight line type to group the bottle, the bottle way, causes to fill installs the function to expand, each kind of shape vessel, all can fill the attire effectively in this equipment.

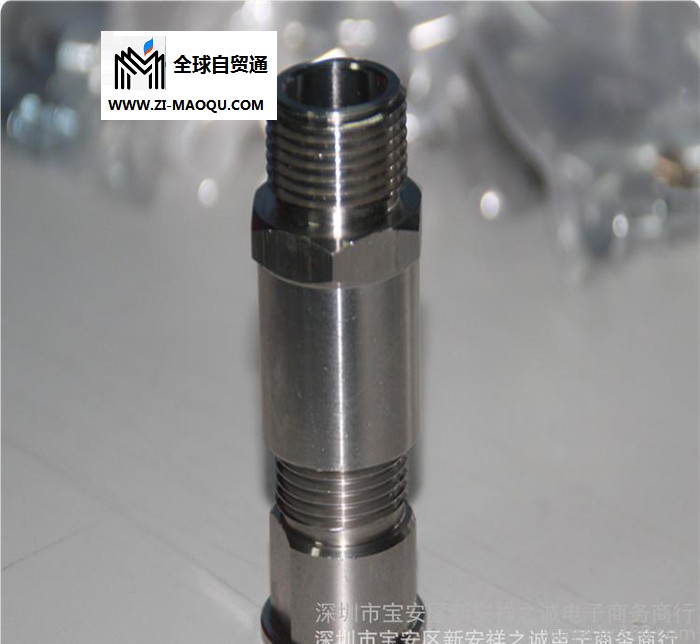

Selects the international advanced gas to fill installs the valve, guarantees fills installs the process not to have the dripping of a water clock, not to drool.

The formidable PLC software support, may realize ideally fills installs the work.

The man-machine friendly contact surface, all operations complete on the touching type colored tablet. ③The precise measurement control

fills the attire to use the fixed flow channel parameter, the control fills installs the time to realize the different measurement to fill the attire.

The pneumatic valve fills the precise time which installs to be possible to establish to 0.01 second, can cause the measurement precision control at±1% erroneous scope, reduces the nonessential material loss, enhances the user economic efficiency.

Each fills the pattern the measurement to be possible to carry on the independent control, realizes fills installs the measurement the consistency.

The this aircraft established has entered the bottle technology procedure, does not have the bottle, the counting does not arrive does not fill the attire, only then when the counter recorded the bottle number filled the bottling number consistently with the hypothesis when only then starts to fill the attire.

Fills the load how many, may carry on when initially moves must fill the load, again carries on the trimming, then obtains ideally fills installs the measuring accuracy. ④The technical reference

fills installs the scope 50~1000 milliliters

to fill installs the speed <90 bottle/The minute (refers to 100~500 milliliters scopes)

to measure the precision±1%

rated power 0.8 kilowatt

working voltage 220 volt

work barometric pressure 6~7 kilograms/Square centimeter

gas consumption 0.5 cubic meter/Minute

machine net weight 650 kilogram

external dimensions 2000×870×1900 millimeter |